Case Study

2024 Nov 26

Coating and Laminating Machines : A Comprehensive Guide

In the fast-evolving world of industrial manufacturing, coating and laminating machines have become indispensable. These advanced technologies are widely used across industries to enhance product durability, improve functionality, and achieve superior aesthetics. From packaging and textiles to electronics and automotive sectors, coating and laminating machines are driving efficiency and innovation. This guide dives deep into their functionalities, benefits, and future trends, while showcasing a real-world success story from Dubai, where custom solutions revolutionized the market.

What Are Coating and Laminating Machines?

Coating and laminating machines are specialized equipment designed to apply layers of material—such as films, adhesives, or protective coatings—onto surfaces.

- Coating Machines:These machines apply liquids, such as paints, varnishes, or adhesives, to enhance the surface properties of materials.

- Laminating Machines:Laminators bond two or more layers of material together to improve strength, durability, and appearance.

Their ability to deliver precision and consistency makes them essential for industries like flexible packaging, medical devices, and construction materials.

Types of Coating and Laminating Machines

There is a wide variety of coating and laminating machines, each tailored to specific industrial needs:

- Industrial Coating Machines : Designed for high-precision applications like adding protective layers on electronics or textiles.

- High-Speed Laminators : Ideal for mass production, commonly used in the packaging and printing industries.

- Solvent-less Laminating Machines : These machines utilize solvent-free adhesives for laminating, offering a breakthrough in sustainable production.

- Environmental Advantages : Solvent-less technology eliminates the emission of volatile organic compounds (VOCs), reducing environmental impact.

- Cost Efficiency : Reduced energy consumption and the elimination of waste treatment requirements make these machines ideal for businesses aiming for low operational costs.

- Applications : Widely used in industries like food packaging, pharmaceuticals, and others that require high safety and sustainability standards.

- Custom Machines:Tailored to address unique challenges and niche market demands, offering unparalleled versatility.

The advent of solvent-less laminating machines marks a significant step forward in eco-friendly production, making them the preferred choice for many manufacturers.

The Dubai Success Story: How Custom Solutions Won the Market

Dubai, a global hub for trade and innovation, has always prioritized adopting cutting-edge technology. The city’s manufacturing and packaging industries faced a challenge: meeting high demand for premium-quality products while maintaining efficiency and sustainability. Custom coating and laminating machines became the solution to this pressing need.

Understanding Dubai’s Market Needs

Dubai’s economy, driven by sectors like luxury goods, real estate, and high-performance materials, required machinery that could deliver exceptional quality. Traditional machines couldn’t address the unique demands of these industries, such as handling specialized materials or ensuring eco-friendly production processes.

The Role of Custom Coating and Laminating Machines

Manufacturers began to design bespoke machines specifically tailored to the needs of Dubai’s industrial players. These machines introduced:

- Enhanced Precision:Perfectly suited for intricate applications like decorative laminates and flexible packaging.

- Efficiency Gains:Reduced waste, minimized downtime, and optimized production speeds.

- Eco-Friendly Innovations:Supported the use of sustainable materials and energy-efficient processes.

Results and Market Impact

Custom solutions quickly yielded measurable results:

- Businesses reported a 25% increase in production efficiency.

- Dubai-based manufacturers gained a competitive edge in the global market, catering to clients demanding high-quality, customized solutions.

- Success stories, such as a luxury packaging firm doubling its output with minimal waste, highlighted the transformative potential of these machines.

This story from Dubai exemplifies how innovation and customization can align perfectly with market needs, reinforcing the significance of tailored machinery.

Key Benefits of Coating and Laminating Machines

The advantages of coating and laminating machines extend beyond Dubai’s borders:

- Improved Product Durability:Protective coatings and laminates add strength, making products last longer.

- Enhanced Aesthetics:Glossy laminates and decorative coatings enhance visual appeal.

- Cost-Effective Production:Automated processes reduce labor costs and material wastage.

- Customization Flexibility:Machines can be tailored for specific materials, shapes, and sizes, catering to niche requirements.

- Sustainability:Many machines now support eco-friendly adhesives and coatings, aligning with global environmental goals.

Factors to Consider When Choosing a Machine

When investing in coating or laminating equipment, businesses should evaluate:

- Material Compatibility:Ensure the machine suits the materials you work with, such as plastics, paper, or textiles.

- Production Requirements:Match the machine’s speed and capacity to your output goals.

- Customization Options:If you operate in a specialized market, consider machines that offer tailored solutions.

- Maintenance and Support:Reliable after-sales service is critical for minimizing downtime and ensuring long-term productivity.

Conclusion

Coating and laminating machines are vital tools in modern manufacturing, enabling businesses to meet high-quality standards while optimizing efficiency. Their adaptability, as seen in Dubai’s success with custom solutions, proves that tailored approaches can unlock immense market potential. Solvent-less laminating machines, in particular, exemplify how innovation can align with sustainability goals.

As technology continues to evolve, investing in advanced, eco-friendly, and customizable machines will be critical for staying competitive in an increasingly demanding global market. Whether you’re a packaging company, a textile manufacturer, or a technology innovator, these machines offer the precision and versatility required to excel.

Ready to Find the Right Solution? Consult Us Today!

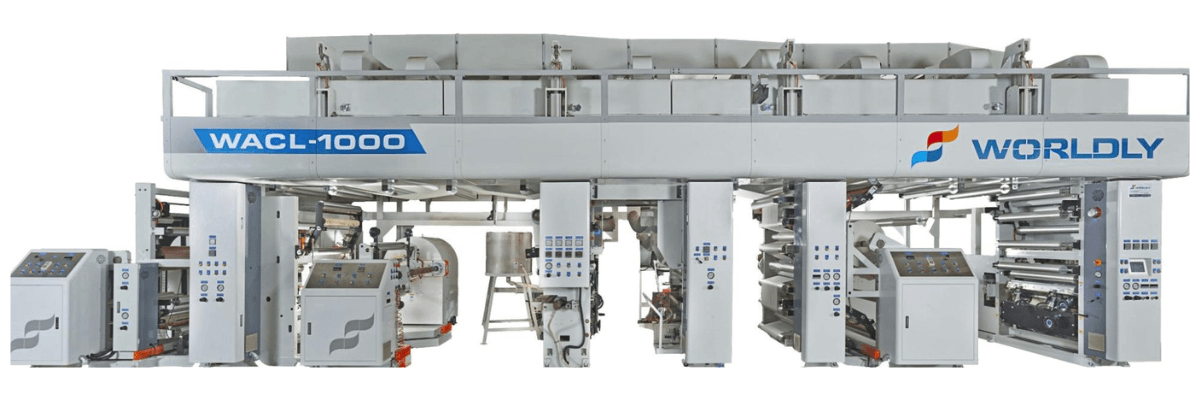

At WORLDLY, we specialize in providing state-of-the-art coating and laminating machines tailored to meet your specific needs. Whether you’re looking for standard equipment or custom-built solutions, our team of experts is here to guide you every step of the way.

Contact us today for a consultation and discover how our machines can transform your operations and help you stay ahead in the market.

Let us help you achieve your goals with precision, efficiency, and innovation. Get in touch now!