Ink resistance material of furnishing roller optimized ink circulation, avoid cylinder cell ink stock and improve printing quality. The roller driven by motorized can manual or automatic mode synchronized with printing speed.

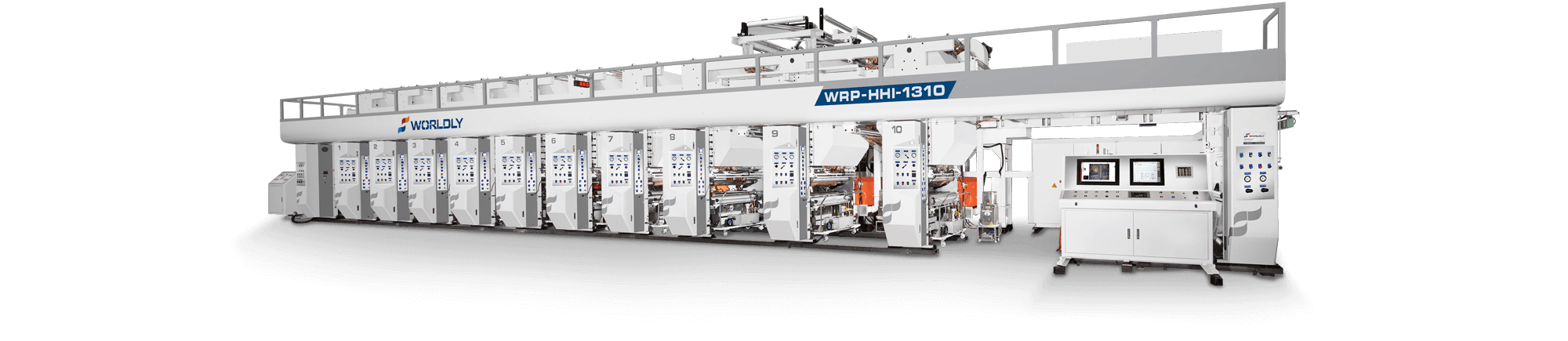

Specifications

| Model | WRP-HHI |

|---|---|

| Maximum Machine Speed | 350 m/min |

| Printing Maximum Speed | 330 m/min |

| Printing Width | 1000 mm / 1200 mm / 1300 mm |

| Printing Cylinder | 350 mm - 900 mm |

| Material Diameter | Ø800 mm / Ø1000 mm |

Applications

PET, CPP, PVC,OPP, PP, PE, Nylon, Aluminum Foil, Paper.

PE Printing

PE Bags

Wood Pattern Wallpaper

Shrink Label

Instant Noodle Bags

Flexible Packaging for Energy Drinks

Snacks Bags

Candy Wrappers

Yogurt Cup